In the modern world of electronics, circuit card play a central role, acting as the backbone of nearly every tool we depend on, from smart devices to innovative industrial equipment. At the heart of these advancements is the printed circuit board (PCB), a fundamental element that connects numerous electronic components and assists in the operation of electronic circuits. The demand for top quality PCB fabrication and assembly has risen, resulting in the introduction of many PCB manufacturers across the world. The diversity in types of motherboard, such as flexible PCBs, rigid-flex circuit card, and high-density interconnect (HDI) PCBs, caters to the varied demands of industries varying from consumer electronics to telecoms.

A printed motherboard is essentially a slim board made from a non-conductive product, such as fiberglass, to which pathways and links for electronic components are printed or etched. Their design and assembly are critical, and companies that specialize in PCB assembly typically supply an array of services consisting of prototyping, production, and assembly of these vital components. By utilizing innovative PCB manufacturing methods, manufacturers are qualified of creating circuit card that satisfy the rigid demands of high-frequency applications, such as those located in superhigh frequency (RF) communication circuits. This consists of the competence to design and make high-frequency PCBs that can take care of the facility characteristics of RF circuits, an important facet these days's communication modern technology.

The process of PCB assembly normally entails several key stages, including soldering components to the PCB, testing for top quality guarantee, and making sure the last item meets both regulatory standards and customer requirements. In addition, the rise of quick turn PCB services has dramatically lowered the lead time for manufacturing circuit boards, allowing companies to innovate faster and bring products to market extra quickly.

When it concerns PCB fabrication, manufacturers may provide a range of choices, from conventional FR-4 materials to advanced materials like Rogers 4350B and Megtron 6, which are designed for high-performance applications. Each material brings its very own collection of benefits, such as enhanced thermal conductivity and lower signal loss, making them suitable for specific applications in industries such as aerospace, clinical, and auto industries. In addition, the capacities of manufacturers have actually broadened to include not only basic PCB assembly but likewise custom PCB options, allowing organizations to bring their one-of-a-kind designs to life. Custom PCB fabrication services make it possible for clients to specify the exact dimensions, layer matter, and materials required for their job, guaranteeing compatibility with a variety of electronic designs.

Flex PCBs, or flexible printed circuits, represent one more specialized area within the PCB market. The advancement of flexible PCB modern technology has actually opened up brand-new opportunities in item design, especially in mobile devices, wearable technology, and medical gadgets.

Successful multilayer PCB assembly demands exact alignment and cautious factor to consider throughout the design phase to stop signal interference and guarantee ideal efficiency. Advanced techniques, like blind and buried vias, have actually emerged to satisfy these intricacies without endangering the efficiency and performance of the PCB.

An additional important factor to consider in PCB engineering is impedance control, which click here is vital for making certain signal integrity, particularly in high-speed applications. Designers have to carefully evaluate the physical layout of circuit traces, the product homes of the PCB, and the link strategies to maintain consistent impedance across the board. Integrating these principles into PCB design not only improves performance however likewise adds to the integrity of communication circuits and high-frequency applications.

For companies aiming to streamline their PCB production process, turnkey PCB assembly services can be a suitable option. These services envelop all phases of production from fabrication to assembly and more info screening, under one umbrella. This technique not just reduces the time required to turn design principles right into completed products but also simplifies supply chain monitoring by lowering the demand for numerous suppliers. The capability to acquire all components and assembly services from a single source boosts performance and can cause cost savings, specifically for high-volume production needs.

The competition amongst PCB manufacturers has brought about an increased emphasis on high quality and innovation, with several firms applying extensive quality assurance processes to guarantee their circuit boards fulfill industry requirements. Qualifications like IPC-A-610, which regulates the reputation of electronic assemblies, play a vital duty in assuring consumers of the reliability and toughness of their products. Manufacturers need to count on cutting edge examination technologies, such as automated optical evaluation (AOI) and X-ray evaluation, get more info to discover defects early in the production process, thus minimizing waste and boosting overall product high quality.

The ecological impact of PCB production has also come to be a substantial concern in recent times. As companies end up being much more ecologically mindful, PCB manufacturers are embracing sustainable practices, including the use of eco-friendly materials and the implementation of waste decrease campaigns. Furthermore, laws concerning the disposal of electronic waste, such as the European Union's RoHS regulation, have influenced manufacturers to reduce making use of dangerous substances in their products, cultivating an industry-wide change toward greener production techniques.

In the realm of development, recent advancements in PCB technology have actually presented interesting possibilities. Some manufacturers are exploring the integration of expert system (AI) and artificial intelligence into the design and assembly processes to enhance precision and predictability. These innovations can promote flexible knowing based on production information, enabling manufacturers to derive understandings that aid enhance efficiencies and lower flaws even more. As electronics proceed to progress, so too does the relevance of ingenious strategies to PCB design and manufacturing.

Small-scale prototyping has actually additionally developed dramatically, enabling companies to check designs quickly before dedicating to bigger production runs. Prototyping not only enables designers to recognize potential design problems yet also offers a chance for optimization, making it possible for customized modifications that can make a significant difference in the last efficiency of an electronic gadget. The ability to supply high-quality prototypes in a short timeframe complements the fast speed of product growth that identifies today's technology landscape.

As demand for electronic tools remains to rise, the demand for innovative PCB options will just grow. The rich variety of PCB designs, ranging from circuit card assemblies to specialized high-frequency designs, underlines the crucial duty that these boards play in making it possible for the capability of contemporary electronics. With continuous improvements in manufacturing innovations, flexible designs, and material sciences, the future of PCB production looks encouraging. Proceeded partnership between end-users, developers, and manufacturers will certainly be crucial in driving the future generation of advancements that will shape the electronic landscapes of tomorrow.

To conclude, from the standard circuit card to the highly innovative multilayer designs and flexible circuits that adapt to innovative applications, printed motherboard represent the core of electronics. The versatility, integrity, and performance of these components consistently drive markets to look for remarkable capabilities in PCB manufacturers. With the most current advancements in modern technology, the production of PCBs is becoming a lot more reliable, eco-friendly, and tailored to the progressing demands of a progressively electronic world. As we look ahead, the integration of new products, designs, and fabrication techniques will unquestionably play a crucial role in transforming exactly how we engage with modern technology, leading the way for innovative electronic applications in the years to find.

Anna Chlumsky Then & Now!

Anna Chlumsky Then & Now! Yasmine Bleeth Then & Now!

Yasmine Bleeth Then & Now! Val Kilmer Then & Now!

Val Kilmer Then & Now! Destiny’s Child Then & Now!

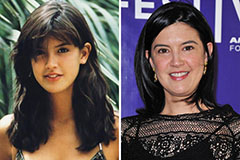

Destiny’s Child Then & Now! Phoebe Cates Then & Now!

Phoebe Cates Then & Now!